Stainless steel CNC machining for industry

A production line at your service

We are specialists in the CNC machining of stainless steel for the production of fittings and custom-made parts. Supplier of stainless steel fittings for the industry, our workshop is internationally recognized for its know-how.

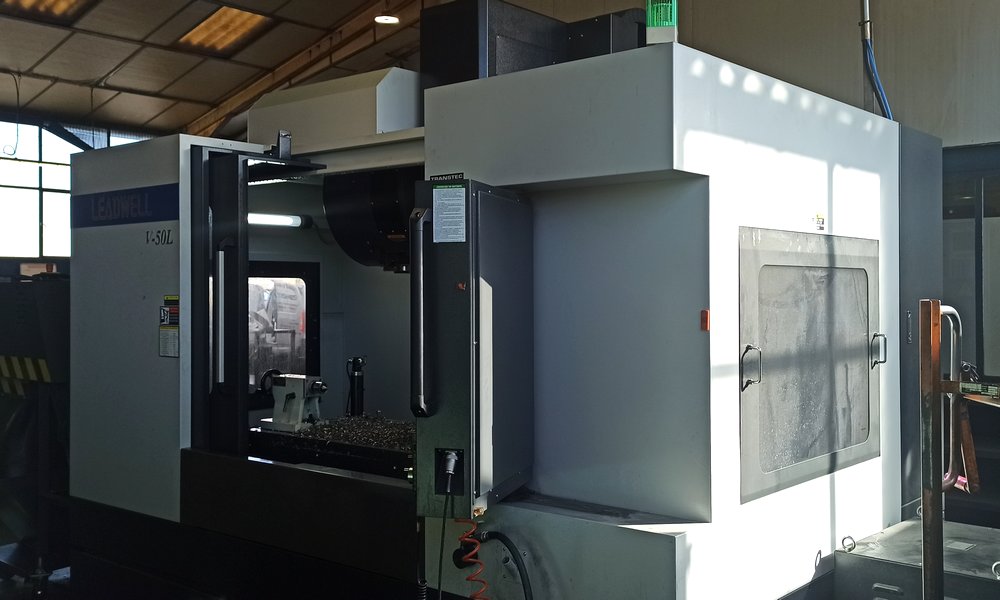

We have a complete machine park, frequently renewed, to manufacture technical steel parts in the best time.

- 18 numerically controlled lathes

- 3 numerically controlled machining centers

- 1 TIG welding unit

- 1 micro-percussion marking unit

- laser engraving unit

- 1 inkjet printing unit

- electropolishing unit

- 1 spectrometer for material analysis

Custom stainless steel parts machined in France

French specialist in stainless steel CNC machining for more than 60 years, we design and manufacture high quality fittings and accessories, from small to medium series, for pharmaceutical, chemical and food installations. Stainless steel fittings conforming to SMS, DIN, ISO, IDF, Macon, RJP standards are our specialty.

Our strength : integrated production facilities, from machining to marking, welding, polishing or quality control. The whole process of steel machining as well as the finishing of the products are carried out in our workshop in France. Our know-how also allows us to machine superalloys (Inconel®, Hastelloy®, Uranus®, Duplex…)

No subcontracting, we guarantee the traceability of products and the respect of deadlines. Simplicity, speed, reliability: for more than 50 years, Beal Inox has been trusted by industrialists in advanced technologies, from oil to chemistry, from food processing to pharmaceuticals, to ensure the quality of their production equipment.

We manufacture standard size stainless steel parts and we also create custom-made parts according to drawings, meeting specific needs, up to 400mm.

A complete stock of raw materials for our production

We have a large stock of raw materials covering all production needs and enabling us to ensure the best possible lead times in the manufacture of your stainless steel parts.

- Machining of stainless steel 1.4404 1.4307 1.4435 1.4539 1.4362 1.4462 1.4542 and special alloys with high resistance F53 F44 410 INCONEL HAST C22 C276 … meeting the STANDARDS EN 10204 EN 10221 CLASS C EN 10060 EN 10308 CLASS 4 ASTM A 388

- Compliant with EC directives 2000/53 2002/95 2003/11 2005/618 and PED 97/23/EC.

- Impact test ASTM A370 at -101°C on request. Pressure test up to 400 bar.

For maximum quality, the raw material used is of European origin, with a certificate of origin.